Tangchi Tarpaulin

20 years plus experiences of manufacturing.

The application scope of tarpaulin mainly includes the following aspects:

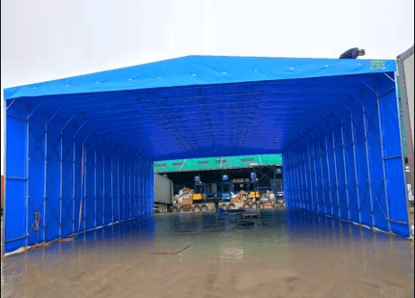

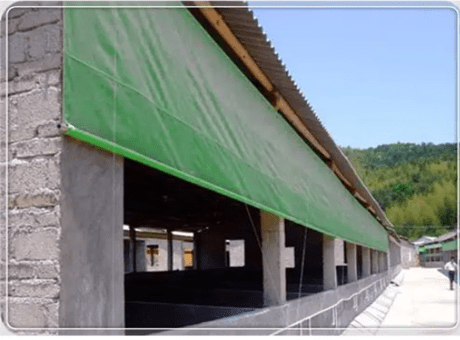

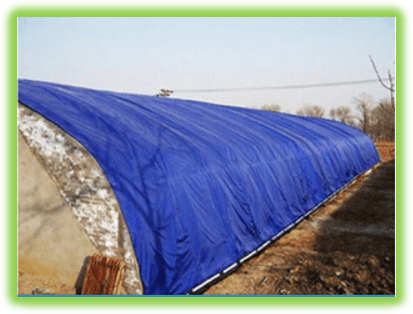

Tarpaulin is mainly used to cover the wet, flammable goods and other goods that need to be covered with tarpaulin during truck transportation. In addition, tarpaulin is widely used in various occasions that require waterproofing and dustproofing, such as construction sites, power construction sites, temporary warehouses, and temporary warehouses.

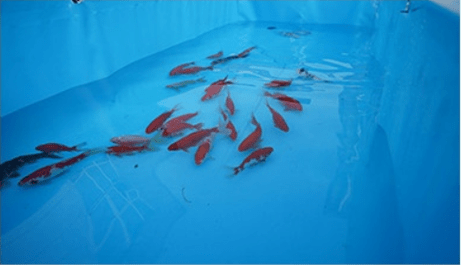

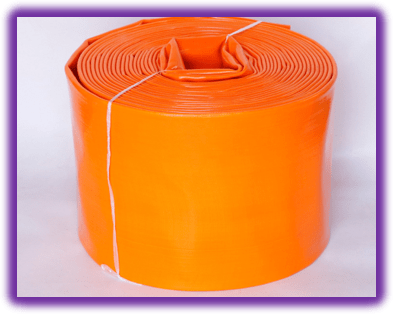

Tarpaulin can be divided into different types according to material and use. The common tarpaulin includes PE tarpaulin and PVC tarpaulin(Tangchi makes). PE tarpaulin is cheaper, but its sunlight resistance is poor. PVC tarpaulin (Tangchi products) has better waterproof and sun protection effect, but the price is higher, suitable for truck waterproof, oil field anti-seepage, factory raw material sun protection, etc.

The specific uses of tarpaulin are very extensive. It can be used for temporary grain storage and various outdoor cover of crops, as well as temporary warehouses and warehouses for construction sites, power construction sites and other construction sites. In addition, tarpaulin can be used for cargo cover of cars, trains, ships and cargo ships, as well as cover of coal plants or goods with sharp edges.

First, the widest range of products: Our company’s PVC tarpaulin base cloth uses four categories, including high-strength polyester fabric, high-strength industrial thread fabric, glass fiber fabric, and organosilicon fabric (the same industry usually only produces one or two of these), making it convenient for customers to purchase in one stop.

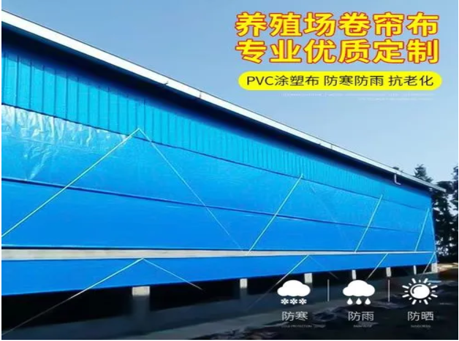

Second. Our PVC tarpaulin is customized according to customer needs. It is coated with PVC paste resin mixed with flame retardants, mold inhibitors, anti-aging agents, anti-static agents, and other chemical auxiliaries to achieve different waterproof, mold-resistant, cold-resistant, aging-resistant, and anti-static properties.

Third, our company can flexibly customize the thickness, weight, and breaking strength, tear elongation, and tear strength of the product according to customer requirements. For example, for 2*2, we can customize the weight to be between 420g and 700g (the technical upper limit for 2*2 in the same industry is usually 550g-600g).

Tarpaulin has functions of good weather resistance, flame retardant, fire prevention, high strength, wear resistance, long service life and so on.

What are the performance characteristics of the tarpaulin sold on the market now?

1, air permeability: tarpaulin must consider its air permeability, especially the military tent cloth, the influence of air permeability factors are cloth organization, density, material, waterproof finishing agent type, resin adhesion amount. With the increase of resin adhesion, the air permeability of the tarpaulin decreased. Of course it depends on the finishing agent used. Generally, most of the tents with air permeability are short rape fabric products such as cotton, vinylon, varnylon and so on, which are finished by paraffin or acrylic resin.

2, tensile strength: tarpaulin in use to withstand a variety of tension, such as fixed tension to be subjected to tension: during the use of wind, rain, province and other additional forces. In spite of these external forces, they are still required to maintain their original shape and not easily deformed, which requires that the tarpaulin has a high tensile strength, and there should not be too much difference in longitude and latitude tensile strength. In particular, the tensile strength of the large tent used as an inflatable building is extremely important. Generally, the base cloth is made of high strength polyester, Vinylon and other long fiber fabrics. Waterproof finishing by vinyl chloride resin, chlorinated sulfonated polyethylene resin. The strength of the product is mainly determined by the strength of the fiber material and the density of the fabric.

3, elongated leather and dimensional stability: as eaves and large awnings, it is often used under tension. Fabric elongation should not be too large, its dimensional stability is determined by the creep characteristics of the material.

4, tearing strength: tarpaulin damage is mainly caused by tearing, so tearing strength is an important indicator of tarpaulin. The tear strength is related to whether the tarpaulin will break due to the action of flying foreign objects or for some reason expand around the formation of holes, forming large structural cracks. So, when the tension is high. The canopy fabric is required to have both high tensile strength and high tearing strength.

5, water resistance: water resistance is an important characteristic of tarpaulin, through the impregnation finish, the vinyl chloride tree filling in the gap of the fabric to form a film. If the amount of resin adhesion per unit area exceeds a certain degree, water resistance is not a problem. If the film is thin and subject to bending, soft rubbing or surface wear, the film is easy to break, which may cause mud and water.

6, flame retardant: From the use of safety mountain hair, the tarpaulin is required to have better flame retardant. Flame retardancy can be obtained by selecting flame retardant fibers and substrates. It can also be achieved by adding flame retardancy to the coating agent. The amount of flame retardant added has a direct relationship with the flame retardant effect.